Preparation of the Feedstock

A binder is mixed with metal powder to produce a binder-metal mixture, called a feedstock. The binder gives the mixture a certain plasticity and allows the part to be shaped during the printing process. The mixture is thoroughly homogenized to ensure even distribution of the binder in the metal powder.

Then the filament extrusion takes place, before the material is rolled up, a quality process takes place, the diameter and roundness is measured in 2-axis to support the subsequent printing process in the best possible way.

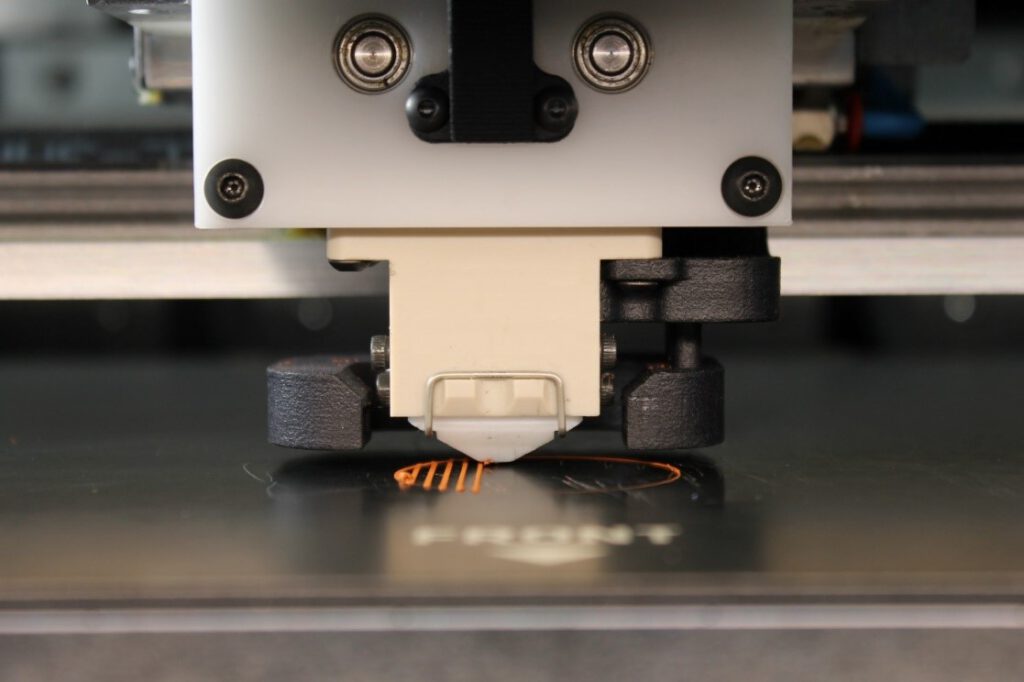

The filament consists of metal powder and a plastic mixture that melts at 130 °C – 150 °C. During the process, the filament is fed to a hot nozzle in the so-called print head. There it is melted and pressed out of the nozzle opening (0.3 mm – 0,8 mm). The extruded filament material is deposited in tracks according to the target geometry.

After a level has been completely printed, the construction platform can be lowered and the next layer can be applied. This process is repeated until the component is finished.

We recommend a direct drive, which allows the filament to be better guided into the hotend.

Show Image Video

Show Image Video