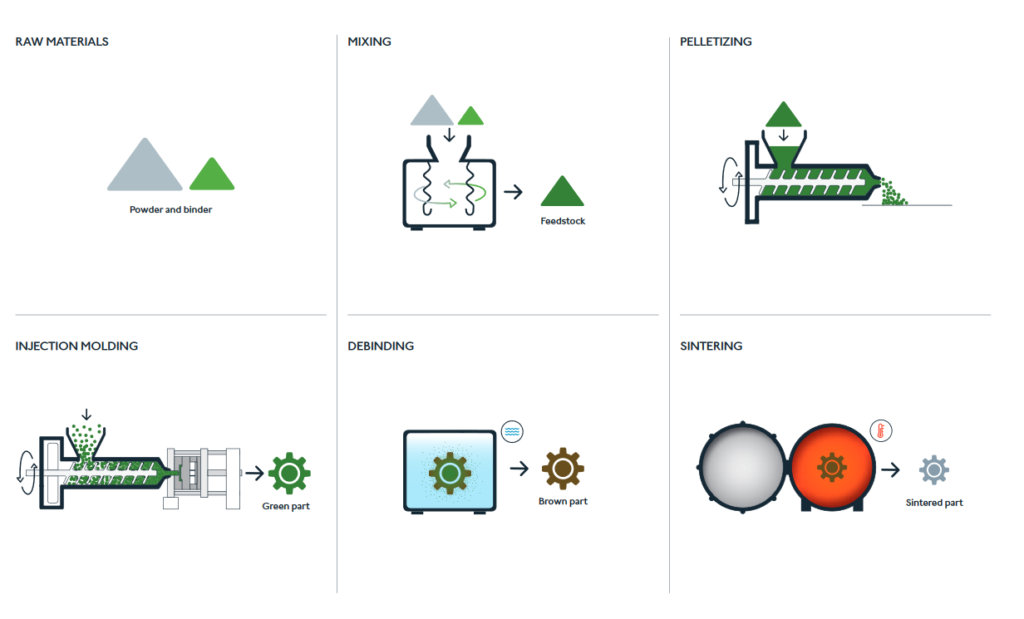

Powder Injection Molding is a process technology used for mass production to produce parts made of metal (MIM = Metal Injection Molding) or made of ceramics (CIM = Ceramic Injection Molding) with complex geometries in a high output. PIM is the ideal process to manufacture complex, functional parts in large quantities and with high material requirements.

Powder injection molding is a cost-efficient mass production process to make small- to medium-sized parts ranging from 0.1 to about 300 g in weight. Main fields of application are precision apparatus engineering, measurement and control technology, medical technology, watch and household technologies, the lock and fittings industry, the automotive and the weapons industry.

Narrow tolerances

The PIM process allows to achieve exactitude better than ± 0.3% of the desired size, without post-processing. This means that with extremely small parts, the tolerance is around a hundredth of a mm. When working with parts that have very narrow tolerances or bigger dimensions, calibration or post-processing might be necessary.

Outstanding surface quality

The surfaces of MIM parts are superior to those of precision casting parts. Even without the polishing treatment, a surface roughness < 1.2 is achieved. Thus, handling and polishing expenses can be eliminated or reduced considerably.

Range of materials

Since MIM parts normally do not require mechanical post-processing, the harder a material is to machine, the greater the advantage offered by the MIM process. This applies especially to stainless steel, soft magnetic alloys, and iron/nickel materials, but also to tool steels and special alloys.

All hardening processes can be applied to MIM parts offhand, just like with comparable solid materials. All the surface treating processes like for example nickel-plating, hard chrome plating, etc. can be applied as well.

Advantages of the PIM application

- All metals can be processed, including titanium and copper, as well as alloy steel and tungsten.

- A wide range of ceramic materials can be processed, including oxide ceramics such as aluminum oxide or zirconium oxide, as well as non-oxide ceramics such as nitrides, carbides or borides including tungsten carbide.

- Complex geometries can be produced without mechanical downstream finishing.

- High precision and repeatability

- High-quality surfaces possible without elaborate downstream finishing

Show Image Video

Show Image Video