Powder Injection Molding, or PIM, is a process for producing complex metal or ceramic parts utilizing a binder. This binder facilitate molding and enables the production of parts with fine detail. The following is a process description for powder injection molding with binder.

Preparation of the Feedstock

A binder is compounded with metal or ceramic powder to produce a so-called feedstock.

The binder gives the mixture a certain plasticity and allows the part to be shaped during the injection molding process.

The mixture is thoroughly homogenized in a mixer, kneader or compounding extruder at up to 140 °C to ensure even distribution of the binder in the metal or ceramic powder.

The binder is used at approximately 35 – 40 vol% which corresponds to about 5 – 15 w% depending on the density of the powder.

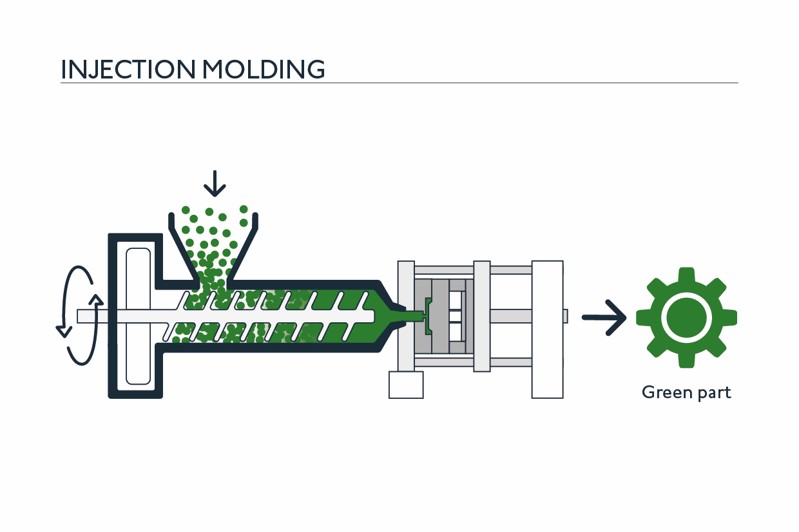

Injection molding

The feedstock is placed in the injection molding machine, which is connected to the mold. The mold is closed and the mixture is injected under high pressure into the cavity of the mold. Due to the pressure and the molding of the tool, the mixture takes the desired shape and becomes a so-called green part.

Typical processing temperatures:

Mold temperature 20 – 30 °C

Processing temperatures injection molding 110 – 150 °C

Show Image Video

Show Image Video