Emery Oleochemicals kicks off metal filament

For several years, the binder system of Emery Oleochemicals has been used in products for the 3D printing market and the company is taking the next step by offering metal filament under the brand LOXIOL.

With this product range Emery Oleochemicals expands its existing business and opens up new markets

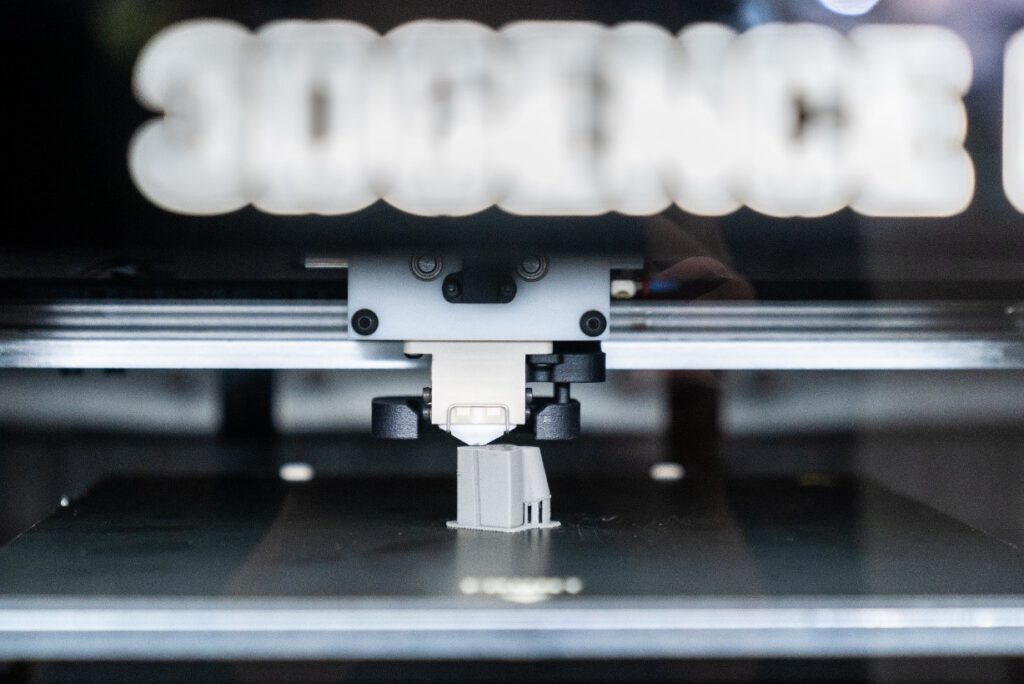

The Fused Filament Fabrication (FFF) process amazes with its low entry barriers, both in terms of the level of investment costs and in the development of know-how.

The filament is molten in the nozzle, which is precisely movable in all three dimensions and thus the material can be applied with pinpoint accuracy. This allows components to be manufactured additively layer by layer. Using a plastic filament, the product is now ready to use, using a metal filament, the printed part is still in green state (“green part”).

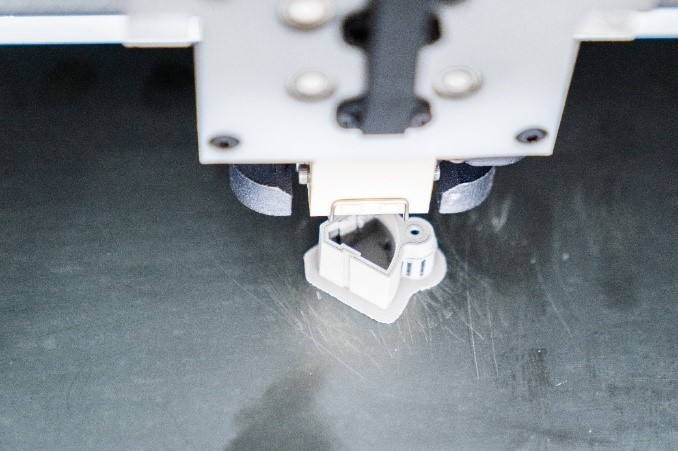

The binder must be partially dissolved from the green part; this is done via solvent extraction. The resulting brown part still requires thermal debinding of residual binder and sintering. This is done in the sintering furnace.

Sustainability benefits

- Support structures from feedstock can be ground in the green state and reused (same for sprue in PIM) ➔ No waste

- 100 percent powder is converted to the final part ➔ Sustainability

- Solvent debinding employed is at least 3 times faster than other debinding systems such as thermal systems or other solvent systems ➔ Quicker time to customer

Technical benefits

- Complicated powder management is completely eliminated ➔ High safety aspect for your employees

- Simple technology ➔ User-friendliness

- Parts can be produced quickly and cost-efficiently

- Standard PIM powders can be used because powder flow properties are not critical ➔ Low material requirements

- Hollow parts possible, especially closed hollow parts ➔ Design freedom

Customizable solutions designed to meet customer-specific needs

To learn more about Emery Oleochemicals’ new LOXIOL Metal Filament product line contact us today at additive-manufacturing@emeryoleo.com

Show Image Video

Show Image Video