LOXIOL Metal Filament

LOXIOL metal filaments are highly flexible metal-polymer composite filaments containing more than 90 percent by weight fine metal powder, allowing printing of parts with high quality surface. Filaments are available in 1.75 mm and 2.85 mm diameters.

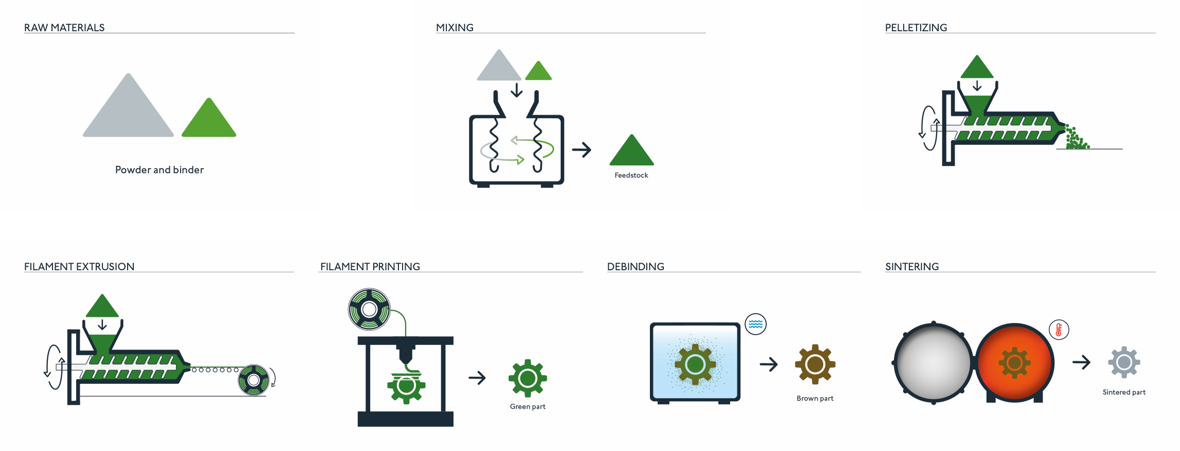

It enables production with conventional fused filament fabrication machines, followed by an industry-standardized debinding and sintering process.

Compared to other additive manufacturing processes using fine metal powder, such as selective laser melting, binder jetting and the like, LOXIOL filament eliminates contact with metal powder, as the powder is embedded in the binder in the filament as well as in the printed green parts.

Almost every commercially available FFF printer can be utilized to print LOXIOL metal filament, however a direct drive with minimum two gears and a hardened nozzle is recommended.

Advantages

- Very fast material exchange

- Easy to use filament for FFF due to the most versatile binder system

- Simple and affordable metal part compared to traditional or other 3D printing methods due to lower machine costs.

- Saves on high material waste costs by using only the material needed for the part.

- Compared to other additive processes using metal powders, such as selective laser melting, binder jetting and the like, Loxiol filament significantly reduces contact with metal dust and particles.

- The printed parts as well as the filament permanently bind the powder.

Show Image Video

Show Image Video