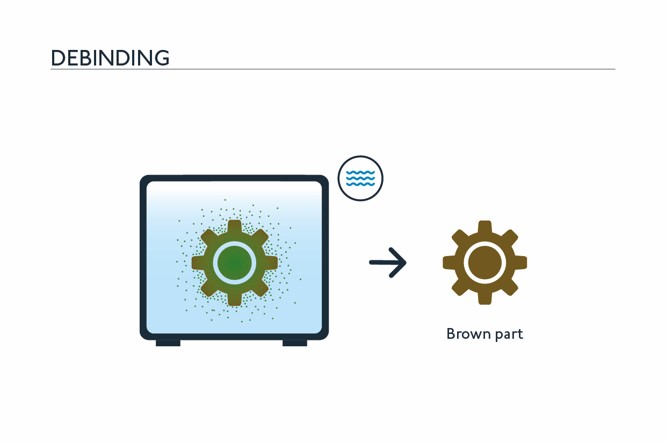

Solvent Debinding:

Green parts are immersed in acetone for 6-36 hours with slow ramp to 40-42 °C. Solvent debinding time depends on size, geometry and wall thickness of part.

Part placement on tray in debinding station and tray type are very important. Perforated trays are best for debinding and allow maximum acetone penetration and circulation in part for optimum debinding. Slight agitation of acetone in debinding vessel should be carried out to allow uniformity of solvent media. The solvent can be reused after distillation.

After the solvent debinding process, the resulting brown part has less than 50 % of the original binder content. A fine porous structure has replaced the share of the binder that has been removed.

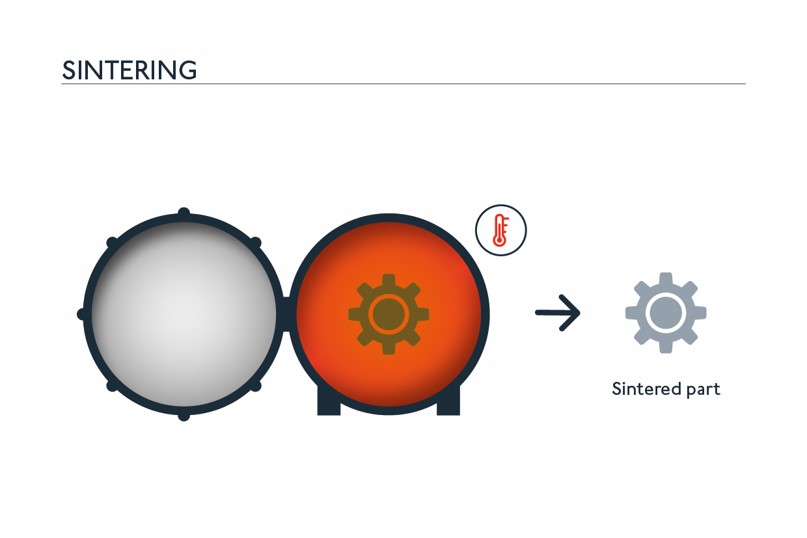

Sintering:

After debinding and thorough drying, thermal debinding and sintering take place by heating the brown part in a furnace. Thermal debinding takes place at 400 – 600 °C.

During sintering, the metal or ceramic particles in the brown part are fused, creating a dense and solid structure. Sintering takes place with controlled conditions such as temperature and atmosphere specific to the respective material.

The brown part shrinks during thermal debinding and sintering as pores disappear and residual binder is thermally degraded, resulting in the final dimensions of the metal part. The shrinkage rate, e.g. for 316L, can be set between 12.5 and 20 % for one dimension.

Post-processing:

After sintering, the parts may undergo a series of post-processing steps to remove burrs or excess material, polish or coat the surface and perform quality checks. The parts are checked for dimensional accuracy and strength and, if necessary, reworked to meet the required specifications.

Show Image Video

Show Image Video