The First Choice in Sustainable Polymer Additives – High Performance and a Greener Alternative

Emery Oleochemicals manufactures high value, renewable polymer additive solutions that offer excellent technical performance. Our Green Polymer Additives product portfolio includes lubricants, plasticizers and viscosity depressants, antistatic and antifogging agents as well as release agents made from sustainable materials that are formulated to optimize production and improve efficiency. Our LOXIOL®, EDENOL® and EMEROX® brands stand for high quality and reliable products for the plastics industry.

Lubricants

LOXIOL® lubricants optimize the processing characteristics of plastics and improve the rheology of the polymer melt by reducing melt viscosity and friction during processing. We offer a wide range of phthalate-free internal and external lubricants for a variety of resins and applications.

- Positive effects on processing

- Low volatility and high compatibility

- Improved rheological properties

- Optimized machinery output

- Improved surface finish of final article

- Transparent and food contact application options

- Product solutions with excellent cell structure in foamed applications

External Lubricants

Our external lubricant solutions help prevent sticking of the hot polymer melt on metal surfaces during calendaring, extrusion, and other processing methods. LOXIOL® G 24 is Emery Oleochemicals’ external lubricant based on 100% renewable resources that is well suited for extrusion of rigid PVC pipes and profiles as well as for injection molding in PVC processing. Key features of LOXIOL® G 24 include:

- Effective external lubricant and release agent

- Low volatility

- Thermal stability over a wide temperature range

- 1:1 paraffin wax and replacement

- Suitable substitute for synthetic Fischer-Tropsch wax

- Reliable supply chain

- High performance, complete lubricant system when combined with LOXIOL® G 59 in Pb or Ca/Zn stabilized PVC formulations

Internal Lubricants

Our internal lubricant solutions help reduce friction and viscosity of polymer melt after fusion and improve dispersion of fillers. LOXIOL® G 59 is Emery Oleochemicals’ innovative internal lubricant with best rheological properties, low volatility and reduced plate-out tendency. LOXIOL® G 59 is highly compatible for rigid PVC processing, and suitable for a wide range of polymers. It optimizes the surface properties of the end product, while it also enhances the production process.

Please click for more product information.

EGDS

Emery Oleochemicals offers different grades of ethylene glycol distearate, customized to meet your requirements.

Please click here to visit our EGDS page.

Release Agents

Emery Oleochemicals’ LOXIOL® release agents improve the injection molding process by reducing friction and allowing for more efficient processing. Our release agents help to minimize cycle times and allow for continuous production. Advantages of using LOXIOL® release agents include:

- Improved surface finish

- Prevention of surface defects caused by the separation process

- Reduced machine wear and cleaning frequency

- Minimized scrap

Pentaerythritol esters are suitable as release agents mainly in polycarbonate and ABS polymers, but also in PET, PA and other plastics. Emery Oleochemicals offers different grades of LOXIOL® pentaerythritol esters. Please click here for more information.

Please click for more product information.

Special Plasticizers

EDENOL® specialty plasticizers improve the processability and performance of plastics and synthetic rubbers. They also impart flexibility and durability to the finished article. We offer a wide range of phthalate-free plasticizers for high performance and technical applications, including both polymeric plasticizers and monomeric plasticizers.

Polymeric Plasticizers

- Compatible with a variety of polymers

- Low migration and low volatility

- Multiple products with food contact approvals

- Viscosity ranges from 650-67,000 mPas at 20°C

- High permanence and weatherability

- Customized solutions available

Monomeric Plasticizers

- Compatible with a variety of polymers

- Low migration and low volatility

- Strong thermal and hydrolytic stability

Please click for more product information.

Viscosity-Regulators

Emery Oleochemicals’ viscosity regulators improve the flow of PVC paste formulations by efficiently reducing viscosity. These products aid in deaeration of the paste system and exhibit low volatility. Applications for these materials include:

Dip Coating

- Gloves

- Electrical equipment, etc.

Rotational Molding

- Toys

- Sporting equipment, etc.

Spray Coating

- Automotive undercarriage coating

- Tray and box linings, etc.

Spread Coating

- Flooring

- Tablecloths

- Tarpaulins

- Wall coverings

- Artificial leather, etc.

Please click for more product information.

Slip Agents

Antiblocking agents/slip agents reduce friction between polymer layers as well as between polymers and processing equipment. Emery Oleochemicals’ natural-based polymer additives effectively improve production by preventing adhesion, especially in winding of film rolls, bag production, and other packaging operations. Our antiblocking agents/slip agents product line includes:

- A variety of products suitable for extrusion

- Grades formulated for high transparency applications

- Cost effective and highly concentrated systems

Please click for more product information.

Antistatic Agents

Static effect in plastics applications Insulating materials including most types of plastics tend to build up static charge by separation of positively and negatively charged particles. This static charge can lead to several problems, especially if it discharges spontaneously.

- Static charge increases dust formation

- Thin plastic films or other light weight plastic parts or particles can stick to each other or to other materials

- A discharge can be painful to consumers, for example in flooring or shoe sole applications

- In industries working with flammable substances or fine powders, a discharge is a severe safety hazard

- Many semiconductor devices used in electronics are highly sensitive to the presence of static charge and can be damaged by a static discharge

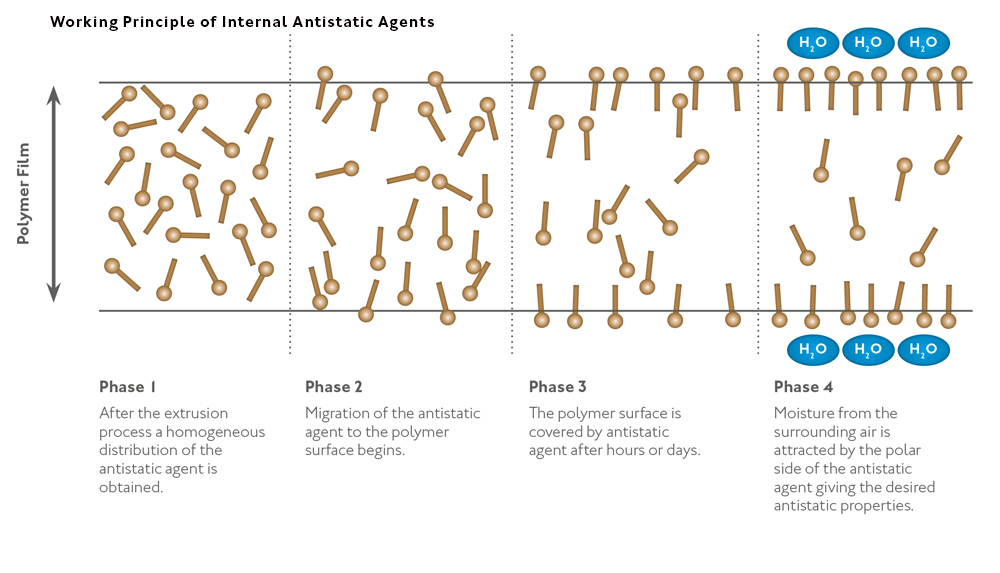

Emery Oleochemicals’ LOXIOL® antistatic agents eliminate buildup of static charge on the surface of finished products. We offer internal and external antistatic agents for a variety of polymers. LOXIOL® internal antistatic agents are designed to be incorporated into the plastics material in the compound or masterbatch. After the thermoplastic conversion like extrusion, injection molding, calendering or compression molding the additive migrates to the plastics surface to avoid the buildup of static charge. Residual antistatic agent in the polymer bulk serves as a reservoir in case the material at the surface is removed in any way. LOXIOL® external antistatic agents can be applied as a liquid solution on finished articles such as films. This method is highly flexible to use, as the antistatic agent is applied only at the very end of the process, and not during extrusion. Advantages of Emery Oleochemicals’ antistatic agents include:

- Minimized risk of electrical discharge that may cause fire or explosion

- Avoidance of electrical shock risk to employees or consumers

- Reduced dust accumulation that affects performance and appearance of plastic products

- Improved handling during transportation, packaging and storage

Please click for more product information.

Antifogging Agents

Fogging is the undesired formation of small water droplets on the surface of films that are used in food packaging and for greenhouses. In both cases there is a rather high difference in temperature and relative humidity between both sides of the film. This leads to condensation of water, which becomes visible as fogging.Fogging is undesired because it reduces the transparency of the film. Packed food is less visible, and plants in greenhouses have less access to sunlight. In case of food packaging, water can damage sensitive goods such as mushrooms. Plants in greenhouses can be flawed by bundled light, as water droplets work as a lens.Antifogging agents solve these issues by altering the surface energy of plastics and/or water. They inhibit the formation of water droplets to create a homogeneous, transparent water layer. Emery Oleochemicals’ Antifogging Agents improve the visibility, quality, and attractiveness of packaged products and help to prevent damage to plants in greenhouse films. Our antifogging agents have food contact approval, and are perfectly suited for the food packaging industry.Particularly in food packaging, our range of antifogging additives enhances consumer product appeal and shelf life while retaining food quality. Additionally, our solutions address common issues with traditional agricultural films by enabling light-transmission and limiting the onset of water droplets, therefore avoiding damage to plants in growing tunnels. Advantages of Emery Oleochemicals’ antifogging agents include:

- Optimized for applications in plastic films

- Highly efficient

- Excellent transparency of the final product

- Food contact approval

- Availability of vegetable-derived products

- Long history of safe use

Please click for more product information.

Polymeric Building Blocks

EMEROX® azelaic acid is produced via Emery Oleochemicals’ proprietary ozonolysis technology which uses the powerful reactivity of ozone to cleave oleic acid into azelaic and pelargonic acid. EMEROX® 1144 azelaic acid was developed specifically for the preparation and modification of high molecular weight polymers. Its unique characteristics makes it an excellent choice for linear polyamides that are formed by the reaction of EMEROX® azelaic acid with diamines. These polyamides use either EMEROX® 1144 as the principal dibasic acid component (e.g. PA 6,9 Nylon) or as a dibasic acid modifier.The introduction of EMEROX® 1144, a linear nine-carbon structure, improves the polymer low-temperature impact strength, without sacrificing high temperature performance of linear polyamides. Furthermore, linear polyamides utilizing EMEROX® 1144 enable products that possess excellent abrasion resistance, low water absorption and high impact resistance.Functional esters of EMEROX® 1144 can be used as components in urethane and as a source of soft segments in co-polyester fibers, imparting good low temperature performance with hydrolytic resistance. EMEROX® azelaic acids, a linear nine carbon dicarboxylic acid, derived from natural, renewable sources can be utilized for a wide range of applications that include nylon engineering plastics and fibers, polyamide hot melts, urethane elastomers as well polyester films and adhesives. EMEROX® azelaic acid is extremely versatile offering a good balance of properties and unique molecule attributes extended to derivatives. Key features include:

- Excellent flexibility

- Improved polymer low-temperature impact strength, without sacrificing high temperature performance

- Excellent hydrolysis resistance

- Low water absorption

- High impact resistance

- Improved solubility characteristics#

- Outstanding low temperature properties

Please click for more product information.

With over 60 years of technical expertise developing plastic additives, we combine proprietary technology with market insight to offer unique solutions for demanding market sectors such as automotive, building and construction, consumer products, film, and packaging. Our Global Technical Development Center located in Loxstedt, Germany, supported by our regional Product & Application Development labs in North America and Thailand, allows us to develop customized solutions and engage in joint product development efforts with our customers on a global scale and offer unparalleled technical support worldwide.

Show Image Video

Show Image Video